Air conditioning

Originates from the system that both cools and controls the humidity of air in a building. It is now loosely used to describe any room cooling application

Air -to- Air Heat Pump

A heat pump that uses air as the medium for both heat source and heat load (heat sink). It extracts energy from the air outside and distributes it indoors using a fan. It can also be used in reverse to cool the building.

Air -to- Water Heat Pump

A heat pump that uses air as the medium for heat source and water as the medium for heat sink.

Ambient temperature

Outside temperature

Antifreeze

An additive that gives water a lower freezing point. Ethylene or Propylene Glycol is most commonly used in heat pump systems. (Note, Antifreeze is not a refrigerant)

Bivalent

When a heat pump operates alongside a boiler or other heating device it is said to be bivalent. There are different control strategies that are usually programmed in the heat pump’s controller. ‘Hybrid’ could be a more familiar term used here

Borehole

Vertical hole drilled in the ground. It can be used to extract heat with a heat pump. Often 100m deep.

Buffer cylinder

Water cylinder or tank which acts as a very short-term store of heat. It is generally fitted to minimise short-cycling, meaning frequent stop/start of the compressor.

Cascade. Used to describe multiple heat pumps, side-by-side, that operate in sequence to control the output. (Note, the term is used differently in low temperature refrigeration)

CO2 heat pump

System where the refrigerant used is Carbon Dioxide and the ‘Transcritical’ cycle gives rise to different characteristics.

Closed loop

System using sealed plastic ground pipes which usually contain a glycol antifreeze. It is the most common trench or borehole ground source system.

Compressor

The heart of a heat pump. With its integral electric motor, it compresses the gaseous refrigerant, enables a pressure difference and enables the ‘up hill’ heat transfer process.

Condenser

Heat exchanger on the ‘hot’ side of the system where refrigerant condenses.

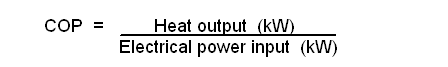

Coefficient of Performance (COP)

The energy-efficiency of a heat pump. Found by dividing the useful heat output by the energy input.

Defrost

Any air source unit used in temperatures of around 7°C and below will need an automatic defrost mechanism. This can be reverse-cycle or got-gas.

De-superheater

A device fitted to the outlet pipe of the compressor to capture a small proportion of the heat at a higher temperature.

Direct Expansion System (DX)

A system where the refrigerant flows directly within the ground pipes. This system is less common, and has drawbacks.

Delta T, ΔT, dt or DT.

Delta is a Greek letter (Δ) that signifies a change in something. Delta T is a difference between two temperatures and is denoted by ‘K’. For example: flow temperature = 35°C, return = 30°C, dt = 5K.

DHW Domestic Hot Water

This the stuff that comes out of your taps. With heat pumps it is always stored in a DHW cylinder. Combi-boilers are direct gas water heaters with no storage cylinder.

Efficiency

Loosely used as ‘effectiveness’

Energy-efficiency – the ‘effectiveness’ of use of energy – the heat output divided by the energy input.

Energy

This is a quantity of ‘power’ over time, and usually expressed in kWh (kilo-watt hours). e.g. a vacuum cleaner of 1kW power would consume 1kWh of energy if used for 1 hour. A 100w power bulb uses 2.4kWh of energy per day.

Emitter

Component that ‘emits’ the heat into a building, e.g. radiators or under floor heating.

Evaporative cooling

Intake air to a room passes over a wet material. The evaporation causes some cooling. Air must be relatively dry. Not effective for re-circulation.

Flow

An old, but still used term, describing the pipe taking water flow out from a stove or boiler. It could also be labelled ‘outlet’. This would seem a better term. The term can be very confusing if used for the ground source. e.g. is it cold flow from heat pump, or flow from borehole.

Horizontal collector

Can be either coiled ‘Slinky’ or straight pipes that are buried up to 2m deep in open ground. The pipe contains a glycol antifreeze solution.

Hot-gas defrost

Less common method of periodically defrosting an air source heat exchanger. Most defrosts are ‘reverse’ type.

Heating Curve

Almost all heat pumps, and many condensing boilers control the heated water temperature (to the radiators etc) using a Heating Curve. To explain – It makes sense to have the radiators warmer when its colder outside. The ‘curve’ setting dictates the water temperature relative to outside conditions. Each manufacturer has a different number setting. Read your user manual for a description relating to your product.

Heat Exchanger

Simple component that transfers heat from one fluid to another. It could be liquid to liquid, liquid to air, air to air.

Heat Meter

An installed device fitted to the pipework that measures heat quantity produced

Hybrid

This is used to describe a system involving a heat pump and a boiler. The system would be controlled such that the heat pump has priority, and the boiler is fired only when the heat pump cannot deliver sufficient heat or a high enough temperature.

Hysteresis

Difference between switch-on and switch-off temperature. It is also called ‘differential’. Not to be confused with hysterics.

Inverter

Electronic device that varies the frequency, hence rotational speed, of a compressor. It is used to vary the capacity of a heat pump.

Mean temperature

This is the ‘average’ temperature. E.g. a radiator, and accounts for hot spots and cold spots.

Open Loop

System where river or ground water is pumped through a heat pump then expelled to the environment a few degrees colder.

Power

Power is usually the electrical rating (Watts). The intensity of a device e.g. a 3 kW (3,000 watt) electric heater, or 100w bulb (using 100w or electricity).

I personally don’t like the use of ‘power’ to describe heat from a radiator. I would use ‘heat output’ (kW) in that case.

Passive Cooling

Cooling without a heat pump. This is achieved by simply circulating the water from the ground directly through the under floor heating system. It is sometimes called ‘free cooling’

Refrigerant

The working fluid within the heat pump. It evaporates in one part and condenses in another. By doing so, heat is transferred in the opposite direction. (Antifreeze is not a refrigerant|)

Return

This term is used to describe the pipe coming back to a boiler or heat pump. This could also be labelled ‘inlet’. It is the opposite pipe to the ‘flow’.

Reverse-cycle defrost

An air source heat pump usually ‘reverses’ to melt ice build-up on the heat exchanger fins.

Rotary compressor

Term commonly used to describe small ‘offset-roller’ compressors as used in small air conditioning units

Scroll Compressor

Compressor which was developed around 1990 and involves two ‘scroll’ shaped components that oscillate relative to each other.

Secondary return hot water loop

Hot water is pumped around a loop to ensure taps run-hot immediately. Commonly used in hotels and large houses.

Set-back

A reduction in temperature-setting for unoccupied or night periods. It is often programmed with daily time settings.

Set point

Temperature setting of a thermostat.

Short-cycling

Term given when a compressor runs for short periods. When it switches on and off fairly quickly.

Sink

The side of a heat pump where the heat is emitted or dissipated for use. Also referred to as the ‘load’ side of the system. This may be an outdated term.

Slinky

Sometimes used to describe the type of ground collector pipes which are coiled before burying in a trench. Slinky is a trade mark.

![]()

Seasonal Performance Factor (SPF)

Similar to COP, but is the total heat over a year divided by the total electrical input. This also takes into account any necessary electric top-up heating load

Seasonal Coefficient of Performance Factor (SCOP)

This is a calculated prediction of the average COP over the year. Source Where the heat is taken from – e.g. the air or the ground.

Star Rating. MCS method of rating radiators and underfloor. 6-star is the lowest water temperature and most efficient.

Thermal mass

Usually refers to a building or item’s ability to store heat, i.e. a high thermal mass item will take a long time to heat up and also a long time to cool down. In essence, it’s the same as specific heat.

Transcritical

Vapour compression cycle where the pressure rises above the ‘critical’ point. This transcends the point where ‘liquid’ or ‘vapour’ states can be defined. Only applies to CO2 refrigerant

Weather Compensation

Automatic adjustment of the heat pump’s output temperature dependent on the outside temperature. A ‘curve’ setting is used to adjust. Different terms are used, e.g. ‘water law’. ‘floating condensation’ is another term you might see.