Here are a few interesting pictures

An Ecoforest ground source heat pump installation. This unit has an inverter drive that varies the heat output from about 4kW to 12kW. The Kamstrup heat meter is showing us that the energy-efficiency is very high. No buffer tank is usually needed.

Below; Good old Swedish IVT Ground Source Heat Pump with integral hot water cylinder

Below; Mitsubishi Ecodan air source heat pump. This unit produces hot water for the underfloor heating system.

This little 3kW Kensa (UK) Shoebox is being installed. It is supplying a nice slate floor heating with 100mm pipe-spacing in an old cottage with no wall insulation. It also provides all the hot water to 65°C in necessary. It’s nice and simple and has been extremely successful.

Here is a straight-pipe ground source trench. 4 pipes in one trench. The pipes are protected with sand before back-filling, unless the fill material is particularly suitable.

Coiled ‘slinky’ coil in a nice wet trench.

With this system, a very large area is  excavated before pipes are laid in a similar manner to underfloor heating. The pipes are protected with sand, then the area is back-filled. This one ended up being very deep and returned very good ground temperatures.

excavated before pipes are laid in a similar manner to underfloor heating. The pipes are protected with sand, then the area is back-filled. This one ended up being very deep and returned very good ground temperatures.

This is a spring source trench where the spring water flows through a gravel bed. The coils are large enough so that no glycol is needed in the system. The spring drops to 8°C in winter, and the circulating water never drops below 4°C into the heat pump.

Underfloor heating designed specifically for use with heat pumps. Awaiting liquid screed.

This shows upstairs that has both floor and wall heating. This type of capillary wall mat can give very low heated water temperatures so gives excellent results

This shows upstairs that has both floor and wall heating. This type of capillary wall mat can give very low heated water temperatures so gives excellent results

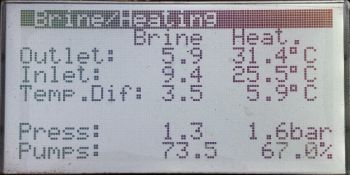

This excellent Ecoforest controller shows all that you might need to know for diagnosis. This is one of many screens that shows the operating temperatures on the ‘cold’ and ‘hot’ side including the circulation pump speeds (percent)

This excellent Ecoforest controller shows all that you might need to know for diagnosis. This is one of many screens that shows the operating temperatures on the ‘cold’ and ‘hot’ side including the circulation pump speeds (percent)

Some archive pictures

From 2006, this interesting Austrian 6kW NEURA ground source heat pump uses relatively benign refrigerant R290. The refrigerant runs directly in the ground pipes (DX). It is also variable (inverter) drive.

From 2006, this interesting Austrian 6kW NEURA ground source heat pump uses relatively benign refrigerant R290. The refrigerant runs directly in the ground pipes (DX). It is also variable (inverter) drive.

This prototype 2kW GSHP unit uses R290 (propane) refrigerant and an efficient rotary compressor. It’s a very simple system for a low-energy house. It has run for many years with almost no maintenance.

(installed 2010, still going strong in 2025!)

Early beginnings, 1979, Comtec Festival Milton Keynes. My second working heat pump. This is a cycle powered demo of an air-water heat pump. It was not until 1980 that I learn that The CFC refrigerant R12 in it was harmful to the Ozone Layer.

65kW DX evaporator for hydro-powered system. loads of copper! It took 2 weeks to build!

Small spring source system from 1990 in Danby North Yorks.

The copper DX evaporator is submerged in a plastic barrel where the spring water passes. The compressor unit (below) is connected to a radiator circuit in the house.

The refrigerant here is Calor Care40, R290 hydrocarbon

Below is the external compressor/condenser (don’t want R290 in the house), and the copper coil is the one in the plastic barrel above