I have been aware for some time that my 5kW air-source heat pump (ASHP) has been using about 3/4 of a kWh/day whilst doing ‘nothing’ over the summer (no circulation pumps running), but recently I have put energy monitors on other ASHPs and was shocked see that these known-brand units are using 2kWh/day when doing no heating at all – I bet the average family use less than that showering! (an 8kW shower for 15 mins = 2kWh).

Whilst in standby mode, is there any reason or excuse for it consuming so much? I think not.

There has, in recent years, been a general focus on standby power since this ‘constantly dripping tap’ can tot-up to a sizeable amount. Highlighting this problem has been very productive – the standby power of most new products has now plummeted.

Let us look at some figures to get a handle on the quantities. Here is what I recorded using pulses monitored from my kWh meter

ASHP on standby 31 watts (average), 0.75kWh/day, 272kWh/ year, (£38 / year)

My A++ larder fridge 7.6 watts (average), 0.182kWh/day, 67kWh/year, (£9.30/year)

Yes you have that right – my fridge, in use, used one quarter the power of the heat pump on standby!

Standby power is however quite hard to measure accurately using any instantaneous devices. This is in part because the current (amps) wave form from modern electronic devices bears no resemblance to a sine wave, and in part since the values are relatively small . For my own satisfaction, so I borrowed a calibration unit to verify the accuracy of the ‘real power’ OpenEnergyMonitor internet-connected devices that I am also using. http://openenergymonitor.org

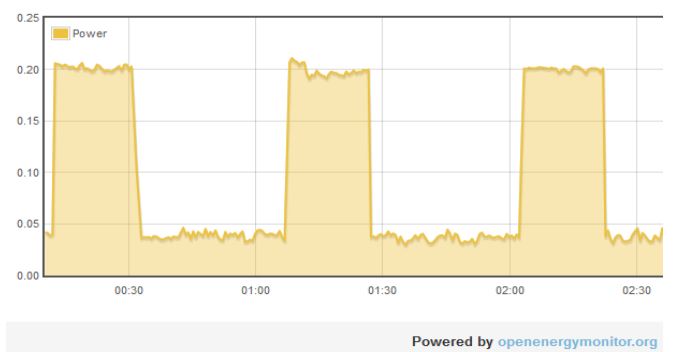

Here is a plot of the 9kW ASHP that is consuming 2 kWh per day (Y axis is in kW).

It alternates between about 35-40 watts and 200 watts.

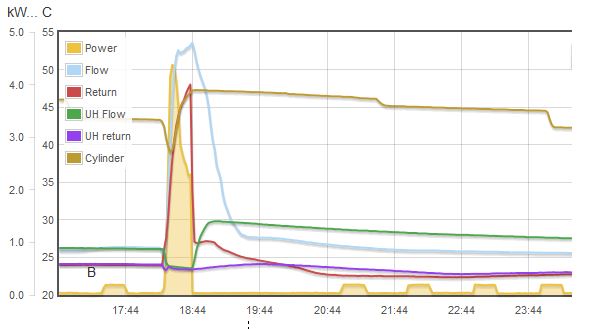

Below is a plot that shows an 8 hr period.. Scale is 0 to 5kW input power.

The buff-coloured area on this 8hr plot relates to energy use, and shows a hot-water cylinder heating ‘hump’ (above 18:44) . This illustrates at-a-glance that the buff-colour area of the standby ‘blips’ (on the bottom axis) forms a significant chunk of the total.

I have previously decried ground source units with controllers that use 15 watts, so why are these particular air-source heat pumps using so much?

The oil inside the compressor can absorb some of the refrigerant. This not only thins the oil, but it can cause oil-foaming at certain times – both can lead to bearing failure due to inadequate lubrication. One answer is to keep the oil warm, and a small electric compressor heater (crankcase heater) can be used for this purpose.

Ground source units are situated indoors, so usually stay relatively warm. I don’t know of any GSHP with a compressor heater. However, air-source are sited outside, and they can experience extreme ‘swings’ of temperature. The worse scenario would be a cold sub-zero night followed by a warm day. In this scenario, the lightweight heat-exchangers warm up, but the heavy compressor can remain the coldest part of the system. Some refrigerant can then migrate to the coldest part (in effect, it condenses in the compressor like water condenses on cold windows). If this cold refrigerant-laden compressor were to start, then there is risk of damage.

The picture shows the compressor with strap-around element heaters. The compressor was quite warm, but one wonders why the lagging around the shell was open at the top; possibly to aid compressor cooling for times when the compressor is working at it’s upper temperature limits?

The picture shows the compressor with strap-around element heaters. The compressor was quite warm, but one wonders why the lagging around the shell was open at the top; possibly to aid compressor cooling for times when the compressor is working at it’s upper temperature limits?What is the solution?

There is a lot of scope here.

Most of these Japanese-type heat pumps are very impressive, they are clearly very well developed and very reliable. Computer-aided fan and heat-exchanger design has led to highly efficient quiet products, and most defrost mechanisms are very well optimised, but are all aspects up to scratch?

It seems already (from graph) that the heater is pulsed, and not simply left on, so why cannot a little more intelligence be added to the controller so that the switching can be controlled more responsibly.

Lagging the compressor should also be possible, and should help, but now one might need to introduce some form of cooling to deal with overheating whist running. There are many options here, and it would take time for a designer to work out the best reliable and cost-effective option that did not compromise over all energy use. I have certainly spent many hours in the past designing crankcase heaters out of systems. The phrase ‘could do better’ springs to mind, and this sentiment should really be directed to the manufacturer’s design office.

A similar situation existed with washing machines many years ago. All for the sake of a thermostat, the hot water feed was blended with cold, just in case the hot feed happened to be at 70C , and could therefore potentially damage clothing. No manufacturer wanted to be blamed for harming any clothes so they all played-safe and kept it simple, to the detriment of energy-efficiency.

My feeling is that we are at the same point with some aspects of ASHPs. Whilst standby power is a small fraction of the total annual consumption, it is still a detail worthy of attention since I’m sure it could easily be improved significantly.

I can think of a simple solution. Make it mandatory to print the standby power on the product label. This would push the manufacturers to give it a little more attention, and sooner or later this unnecessary waste would disappear.

Hi John,

Your very informative article perfectly explains the strange behaviour I am seeing with my recently installed Daikin 9kW ASHP.

I monitor the power consumption with Emoncms. When the pump was first installed the standby power was about 15W. I noticed the standby power had increased to between 30W and 50W about 3 weeks ago. Looking at historical data it was fluctuating on a daily basis between a peak of about 50W around 5am and a low of about 30W in the early afternoon. The average consumption was about 1kWh per day. Further investigation showed that the standby power had suddenly increased about 8 hours after the heat pump had last been running and then remained at the higher values. For the last 3 weeks there has been no demand for heating and my solar panels and Eddi were heating the hot water tank so no demand to the heat pump for hot water.

My conclusion after reading your article is that the Daikin monitors the compressor temperature. Normal operation of the heat pump keeps it warm enough so no heating is required. However after a period of inactivity a heater is switched on to maintain the temperature. The power to the heater is modulated (not a simple on/off thermostat). I used Emoncms to display the outside temperature on the same chart as the heat pump power consumption and confirmed that peak power coincided with the lowest outside temperature and vice vera.

To confirm my theory I switched off the Eddi and used the heat pump to heat my hot water tank. After the tank had been heated then the heat pump standby power dropped back to about 15W.

I see three possible options:

1. Use the heat pump instead of the Eddi for heating my hot water during the summer.

2. Use the Eddi to heat the hot water and ignore the 1kWh per day wasted power. This would not cost me anything as I have surplus solar energy after charging my home storage battery and heating the hot water tank. I am not paid for exporting surplus energy (FIT tariff – deemed export).

3. Use the Eddi and switch off the heat pump for the summer.

Do you have any thoughts on the pros and cons of these options?

Thanks

Dave

Thanks Dave for your good diagnosis. I guess it’s possible that the compressor heater (often referred to as a crankcase heater) is a PTC resistor. i.e. it automatically draws more power the colder it is. I don’t know, but some are. I turn my ASHP completely in warm weather when not needed. It is unlikely to be a problem at startup, but its very advisable to turn the power on 24hrs before running the compressor (e.g. on standby), such that the compressor can warm up, and refrigerant dissolved in the oil can migrate out of the oil and condense in another part of the system.

Great article, really interesting for me – I have two Daikin high temp heat pumps that push heat into our barn in sunny Suffolk, installed in 2015. It’s been puzzling me for a while why we have stubbornly high summer power use and this could be one reason.

I have a question for you – is it Ok to switch one (or both of them) off when not needed..? There is some vague information around about warm-up times for Daikin units (anything between 2 and 8 hours, but mentioned in the context of initial commissioning).

I do already have an Arduino that enables one or both units in response to demand and I am not at all squeamish about adding a couple of power relays to shut off the juice completely. The warm-up times could be an issue, but I could keep one unit powered for base load and warm the other up when needed, something like that..?

So, do you think that shutting one unit down for an extended period could cause harm if I observed the warm-up time..?

Thanks..!

Michael

PS: Going to order my open energy monitor next…

Hello Michael, I am sorry for the delay. I have been swamped with spam, and your message got lost in the middle of it.

The reason why there is a compressor heater for ASHPs is all to do with oil absorbing refrigerant. At start-up, its a bit like shaking a fizzy drink bottle, then taking the top off… it froths up. (as explained in the blog). The main problem with ASHPs is the day/night temperature variations, and the fact that the air heat-exchangers will sometimes be warmer that the compressor, and refrigerant slowly ‘migrates’ to the oil. I have never seen GSHPs with compressor heaters.

I have not worries turning the mains off of my Ecodan completely, and I am sure that many new systems are started straight-out-the-box with no waiting. However it’s not difficult to switch on 1 day before you set it running. This will cause refrigerant dissolved in the oil to migrate towards the heat exchanger where it should be.

Surely the manufacturers are addressing this unnecessary waste of energy

I wish I had read this prior to purchasing my ASHP. My September use increased from 73 KWH to 163 KWH for the month.The fitters said it was my fridge. A meter has been fitted to the indoor and outdoor units which confirms my figures. It is turned off because the increased pressure caused my radiators to leak All replaced then the valves went. Still turned off as the feed pipes are leaking. Waste of space

Newer altherma 8kW has 15W standby usage.

This is measured during summer mode and mid season when it only runs during night.

Temps during daytime standby are around 3-5°c while measuring.

The higher output models are less efficiënt in standby mode.

They do not have the same standby mode.

When there is no heat demand for a while, part of the exterior electronic circuit is cut out to save energy.

My Daikin LT 11Kw heat pump has a standby of .4/.5 Kwh, this is an yearly cost of €700 just wasted.

This not a green pump

Hi John,

Our entire gross electricity consumption is ~4.5kWh/day for the family, so 2kWh/d 'standby' plus maybe another 1kWh/d for DHW tank losses would be a bit ugly.

Rgds

Damon