Also see YouTube here (index of other blogs)

It’s great to see how heat pumps are becoming mainstream, and increasingly the norm for newbuild. However, I have noticed ongoing confusion relating to the use of heat pumps in old buildings. The confusion can start with the ‘will it work’ question. Let’s be clear – the right heat pump could be made to heat any building to any temperature we like. But the crux of the issue is the installation cost and the running cost. The question that we should ask is – ‘can we heat old buildings and achieve acceptable energy-efficiency?’ Well… we probably can, and as time passes, it gets better. Let’s drill into this.

On one level, it is quite simple, but on another level quite complicated.

The simple level relates mainly to the circulating heated water temperature required for poorly-insulated buildings, and this directly affects the energy-efficiency; the Coefficient of Performance (COP) – what heat you get out compared to what electricity you put in. This has implications for the environment and also for running costs.

The complicated level relates to where you want the heat and at what times, and this is all wrapped up with the type of building and its use…. Does it have a lot of internal ‘mass’, brick walls etc i.e. is it slow to heat, and thereafter- slow to cool down. Or is it ‘lightweight’ and mostly insulated internally – quick to heat and quick to cool. Add to this is the occupancy; is it occupied all the time, or empty during the day? Then there are off-peak tariffs and possible future ‘smart grid’ to consider.

Don’t put your hopes too high on finding definite answers here on how best to deploy heat pumps on old buildings for all situations, but you may glean something about where and how heat pumps are likely to be most worthwhile, and also where a good grasp of control settings may be needed.

Heat pumps can promise a fit-and-forget technology, but they sometimes need a modicum of user-engagement if the best results are to be achieved. Maybe more-so in poorly insulated buildings.

The easy stuff

As everyone should know by now, heat pumps are very efficient at producing lukewarm water – It’s an easy ride for them. However, as the water gets hotter, the electrical power-input requirements rise too – the energy-efficiency drops and running cost rises.

The obvious solution to this is to use large-area radiators or well-designed underfloor heating. Both can often provide adequate heat with water temperatures well below ‘hot’. (say 30 to 40°C, 85-105°F) for much of the winter.

Here is the nub of the issue relating to old buildings – it’s more difficult (and a more costly installation) to design a heat-emitter system (radiators or underfloor) to adequately heat an un-insulated building. Especially if using the low water temperatures that energy-efficient heat pumps require. By contrast, well-insulated buildings require far less heat, so should not require overly large radiators. They are the ‘low-hanging fruit’ for heat pumps.

Conventional heating has generally been designed with high-output, for short periods. From plumbers to householders, we are all used to ‘turning the heating on’ and feeling warm fairly quickly. However, heat pumps are far happier operating with lower water temperatures, and this is where some confusion can start. Some patience, and also some confidence in the system is required when setting the required low water temperatures. This is because the system will respond very slowly, and you need to plan ahead and let the building to warm up gently. We are now erring towards a more continuously-enabled system, and contrary to instincts, a heat pump system operated like this can use less energy than one operated on an on/off time clock.

Intermittent heating / constant heating…… starting to get complicated

If the heating is required at a constant temperature, e.g. a retirement home, then things are very easy. The radiators may be able to operate ‘warm’ (not hot) all the time, resulting in very high energy-efficiency (high COP).

Keeping your house warm when you are out is generally seen as wasteful… why heat when you are not there? However, if you do operate with a timer, and allow the house to cool down during the daytime or overnight, then you will need to operate the radiators at an elevated temperature so as to ‘catch-up’, and get the rooms back to a comfortable temperature. The COP will be lower at this time, so you get less heat for your money whist operating ‘timed’. But if timed, you need less total heat due to the lower average temperature of the house. That said, heat is stored in the building’s fabric, so heating while you are out at work is not as wasteful as you may first think.

Both factors (on-all-the-time low, or intermittent and high) can tend to balance out. What you gain on one, you can lose on the other, and vice-versa. The best efficiency is likely to be found with far longer run times than we are traditionally used to. Instead of starting heating 1.5 hours before you get up, try 3 or even as much as 5 hours before, but adjust the circulating water temperature down first (or reduce the heating curve).

The thermal ‘weight’ (or mass) of the building will have a big impact here. If the building is an old brick house (heavy), and a set-back (reduced) temperature is programmed for the night or un-occupied day, then the radiators may need to be considerably warmer to provide comfort in the evenings – not helped by the cold walls. So, in this instance, like the race of the tortoise and the hare, the on-all-the-time tortoise can have the edge due to the good COP resulting from the constantly-enabled lukewarm radiators.

On the other hand, if the building has a lot of internal insulation, and few stone/brick inner walls, it will be thermally ‘light’. In this case the ‘catch-up’ to re-heat to a comfortable temperature should be acceptably short, so an amount of night set-back (lower room temperature at night). is likely to be advantageous.

Unfortunately, I don’t have data or evidence to say where the lines should be drawn, but have in the past been surprised how cheap to run some constantly-enabled heat pumps can be.

A word of warning here. Not all system configurations are that easy to ‘optimise’ for maximum energy-efficiency. The aim is to achieve a low operating water-temperatures and still get adequate heating to the building. If you have a weather-compensation heating-curve, the setting will need engaging with, and hopefully reducing. This should be easy to do, and don’t forget that the response time may be slow. Be mindful that simply reducing TRV radiator valves is not addressing the issue here since the heat pump is not ‘seeing’ the lower water temperature that it likes.

The lowest running costs are likely to be achieved with some amount of night set-back. However, it can be easier, with less risk of setting something wrong, to set the system to constant. You can then find the lowest circulating water temperatures that still keeps you adequately warm. It can be worth experiment. Try it and note down daily electricity use.

The bigger picture

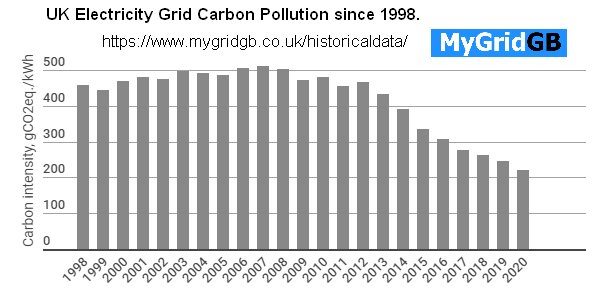

The goal posts in the UK have changed greatly over the last 10 years (say 2010 to 2020). Electricity generation is now twice as ‘green’ and beyond my expectations.

The increase in solar and wind generation, coupled with the phasing down of coal and advent of efficient gas power stations has resulted in the CO2 pollution halving in 10 years. This means that lower COP heat pumps are more acceptable. Added to this, heat pumps have bit-by-bit become more energy-efficient. All-in-all, with a far better selection of energy-efficient products in a now well-established industry, we are far better positioned to install heat pump in all types of building.

Furthermore, there could also some positive advantages for using heat pumps with old ‘heavy’ buildings. The storage of heat in the building’s fabric can mean that we could partly ‘shift’ (in time) the running of the heat pump to coincide with available PV solar, or to benefit from different time tariffs. Future Smart Grids may, in a small way, use the slow-response of old buildings to advantage. We could also ‘incentivise’ and air source system to run at the warmest time of day when its efficiency is high. We are not quite there yet with the necessary ‘intelligent’ controls’ to be able us to control as in these ideas, but it’s coming. I look forward to seeing developments in this area.

Hi,

Would it be worth running a heat pump and using a compost heap in some way to either heat close environment or water circulation?

Hi Kevin, this is not a new idea, and i’m sure its been tried. I have heard of the HeatHeap. This was an enormous heap of rotting vegetation. To get say 5kW (enough to heat a house reasonably well). I understand it was about as big as the house. It had plastic pipes in the heap, and water was circulated to radiators in the house. The heap needs to stay quite warm, and any involvement of a heat pump would cool it off such that the rotting process would stop. I guess the heat generated is simply too small. Keep thinking!

Thanks

Heat pumps are now better than they used to be at doing DHW, so I wouldn’t rule that out. Most installations would do both heating and DHW.

15mm pipe should be fine, BUT it depends how long they are and how big the rads are. You might want to consider adding radiators (2 in a room) rather than simply making them bigger. Anyhow, the pipe size does need assessing, and only so many kW of heat pump heat should go down a 15mm pipe. This is where you might find that a smaller heat pump (hybrid with oil boiler for peak demand) might fit better with your existing radiators.

Thanks. The installer suggested keeping the oil boiler to heat the hot water and GSHP for the radiators.

Do you think the 15 mm pipes are enough for the larger necessary radiators.

Regards. Jon

Hi. I live in an 1730’s farm house with double bricked walls ( I dont think there’s a cavity- or maybe a small one). The house is 3500 square feet and I use oil at present and am considering GSHP. The pipes to radiators are 15mm. The loft is well insulated

Basically, is it worth my while to change over to GSHP or do I need to keep oil as a back up

Thanks

Older buildings can be a bit harder to get the best performance… the best COP, but many old buildings are reporting good results. It depends how warm you want it. The warmer the harder. Might be best to assess your current energy use.. i.e. your fuel bill history, so you know how much energy is being used. An installer would work out your likely heat needs BUT nobody knows the U value of your walls, so historical use might be a good indicator of actual demand.

You could retain your oil boiler and have a hybrid system. This might be a safer bet. e.g. any installer will worry about you having enough heat, so will probably err on the big size. However, if you have oil, you don’t need to have such a big safety margin, so could have a smaller system, that might be more energy-efficient over the year. If you do go hybrid GSHP, make sure the ground collector is big enough. Try to seek out others with HP systems so you get a balanced opinion.

Would this be true even if the tiles were designed as solar absorbing and the roof area designed as an optimum heat absorbing matrix and possibly retain heat until sunset?

I’m thinking of the costs versus digging for ground source!

The volume of air passing over the tiles/matrix will cool them very quickly. The correct placement of a decent ASHP is pretty efficient in it’s own right, and especially so if the source air is not mixed with the air that has already been ‘cooled’, ie. bouncing the cooled air off a wall that is too close to the front of the ASHP so that it gets sucked back through the heat exchanger and reducing efficiency.

Interesting article.

It would be interesting to hear your comments on the late 2021 government insentives. My feeling is that for older property owners, it would be better to be a late adopter of the new technologies than jump in too early. Would you agree?

Also a thought…

Since the COP efficency is improved by having a warmer heat source, could it be possible to extract the heat from a roof space which is warmed by heat escaped from the building and the sun on tiles?

I imagine this could be achieved best during re-roofing work where ceilings could be properly insulated from above and the airflow channelled from inlets at the eaves on one side to an outlet collection manifold elsewhere.

The cold air being emitted from the heat exchanger outside the roof space.

Re-roofing may be less disruptive than digging up a garden to install ground source heat supply if in fact garden space was available!

I imagine that the roof heat would be highest afrer midday in the winter, probably the best time to start boosting the temperature for the evening!

A fanciful idea or worth building on? I have a 1960 dormer bungalow so the roof space is minimal. Probably averaging a foot between ceiling and tiles, so probably of no use!

Sorry for the delay, I seemed to miss a load of comments.

Your idea isn’t a new one. In the 1980’s, a company was selling a loft ASHP. Problem is.. whilst it may seem hot in a loft, this heat is a slow build-up, and if you start extracting the heat, it soon cools to the same temperature as outside. Furthermore, when loft heat is maximum, its sunny, and heating demand (due to sun through windows) is minimum. Added to that is the drone of a heat pump running in the loft. Sorry not to be more positive about your idea. I think its a thought several have had over the years.

That’s not a heat pump under todays definition. . Sounds like you have a standard air-to-air air conditioning unit running in reverse cycle heating mode. Yes it uses heat pump technology and is excellent for your application. I have done exactly the same for my log cabin. But readers may think this is the same as the “heat pumps” that the UK Gov are trying to get people to change over to from gas or oil fired systems. Totally different

Hi, Im in a mid 18th century stone building that we heat with an ASHP (11kw IVT AIRX). We have used cork/lime plaster (diathonite) internally but only maybe 1/5th of the external walls, and only where we had to rip off cement based render. The rest of the walls are just lime plastered 600mm thick rubble stone. The reason we had to take off the internal render is because the walls were saturated from water coming through hairline cracks in the external render which is also cement based. I’d be very wary of using non breathable internal insulation on old walls as the risk of trapping water in the wall (particularly if the external render is cementitious) is very real. Its also next to impossible in an old house to stop warm moist internal air getting behind the insulation and creating mould, or causing joists to begin to rot. A wet wall is going to conduct the heat away much “better” than a dry one. I’d love to see an analysis of U values for a wet stone wall with 50mm PIR backed plasterboard vs a dry stone wall.

On a more positive note 🙂 for our house we focused on good quality windows, air tightness measures (and mechanical ventilation) and insulating the roof. It works. The only bill is electricity which comes in at about €120 a month on average. The house is permanently at around 20C. It is about 250 sq metres over three floors and partially terraced. I don’t have any internal thermostat, just weather compensated control of the ASHP.

A room by room heat loss analysis is easy enough to do and invaluable in sizing radiators and a heatpump. You can also then see the benefit of insulating ceilings, floors and walls, but be mindful that the book values for stone walls tend to be really pessimistic.

Thanks for sharing your experience… Sorry for the delay, I missed this message

Nick I have a similar house to you and am considering a similar install. Could we connect to so I could discuss your experience.

A very interesting article, thank you. I am in the process of installing an Ecodan 8.5kW ASHP in my semi detached 1850’s house.

I have purchased Actis HControl insulation as was going to internally insulate the whole house with this, to allow for better efficiency.

Although I have been reading about breathability of old houses and people have suggested that I should use like plaster and wood fibre boards for insulation.

I really am not sure what to do. Any advice hugely appreciated.

Could I batten out the solid brick walls and use the Actis material, installing some air bricks to allow breathability. Or should I stick with traditional materials and hope this is enough to allow for efficient running of the ASHP?

Thanks!

I’m not an insulation expert, but plenty of people have fitted non-breathable insulation to old buildings. I have done it in our cottage… stuck foil backed insulation onto internal walls. Not noticed a problem yet! The moisture from the house should not be getting into the wall, and unless the insulation is very thick, there should be a bit of heat passing outward through the old walls, so there should be a slight tendency for moisture to migrate to the outside. Otheres will know more than I on the topic.

Did you size the system assuming insulation?

Looking at that product… not that I know much about it, but you need to ensure that the moisture-laden air from inside your house cannot find its way to the cold surface of the stone wall. You also don’t want cold outside air finding its way to the warm side of the insulation. The detail (especially especially along skirting board and ceiling) needs thinking through.

Interesting. But how do you deal with rapidly changing internal and external temperatures due to:

a. Solar gain- our house has a lot of windows, is fairly well insulated and solar gain makes a big difference on sunny days.

b. Climate change and weather that can vary greatly from day to day in terms of external temperatures.

Efficient energy use is of course very important, but comfort is vital too obviously. TRVs will turn off the heat in a room when not needed, but if you’ve had the heating on overnight and then get lots of unexpected warm external temps or solar gain, the heat already in the building can be too much and make the room uncomfortable.

Opening windows might then be an option but that depends on external air temp, wind levels, air quality, noise and security issues, but also may be insufficient to resolve the problem, and the energy used overnight can be wasted and worse, had a negative effect on comfort!

Yes, solar gain can be a problem, and the thing to do is as much shading as possible. Hot countries like Spain and Southern France are better than us at this, auto external shutters are normal and extremely effective. For hot-country dwellers, closing blinds and shutters if you go out in day, is the norm.

This is a very interesting post and has set me thinking. We live in an 1899 detached house with a 1950s extension. We have put in as much insulation as we can and had to have a new condensing gas boiler this last winter which was very expensive as the last one only lasted 12 years. Could we design a hybrid system where a heat pump runs most of the time to provide the base load of heat and the gas boiler runs to top it up in cold weather or to provide hot water. We have a Mitsubishi heat pump / aircom installed in the conservatory and this has been wonderful and solar thermal panels on the roof to provide quite a bit of hot water. Do you have any thoughts on how we might proceed.

Sorry to keep you waiting for a reply. Yes you can have a hybrid system. Many ASHPs have a control for the boiler. This feature has been around for years – used more in Germany that the UK. To be clear, the heat pump may have control contacts that can bring on the boiler if the heat pump needs assistance. It can be a little complex. Some simply ‘hand over’ to the boiler, other systems can run in parallel.

Hello John, this is exactly what I need – a hybrid system, though I have an oil boiler. Not that old and combi. Seems pretty efficient but I’d like to reduce my oil/fossil fuel consumption. I have thermal solar for hot water which directs water to the boiler if not hot enough to go direct to the taps. I have solid, well insulated concrete floors with a (gorgeous and expensive) hardwood finish. I’ve been told I must take this up to install full ASHP for the manifold systems and wider bore pipes which would be insanely disruptive, destructive and expensive. I have solar PV too. I’d love to find someone who can creatively integrate ASHP into this mix, leaving the oil boiler to just top up either heating or hot water when needed.

If would seem daft to disrupt your gorgeous floor, particularly if it’s well-insulated. You may be fine with radiators. If you retain your boiler, you have the advantage of being able to choose a relatively small ASHP heat pump. I tend to think of going maybe 1/2 the normal sizing. A small ASHP would mean it can tick steadily away for much of the year with not-too-hot radiators. The oil can come on as required to top-up. Hard to know how you integrate the PV into that other than a control that tends to put the HP on when its cold and sunny. If the ASHP is small, all this is easier.

Obviously I know little about your system, so whatever you do, do think it through carefully. Keep it as simple as you can.

Good luck with it.

Thank you 🙂 Any suggestions as to a brand of ASHP/manufacturer to talk to? Or a company that is good with hybrid systems?

There are a lot of ASHPs that I am not really familiar with, so not sure how good the hybrid controls are. Most seem to be very simple.. they are set to a specific outside air temperature where it is thought that the heat pump will a) not provide enough heat b) the radiators would need to be too hot for the heat pump. It then switches from HP to the boiler. However, there would be many times in mid winter when your house doesn’t need ‘full power’ e.g. if some rooms are unused or set low, if you are out, you may prefer your heat pump do do its best. The German and Swedish units did have quite sophisticated hybrid (bi-valent) control that would ‘blend’ heat from the HP and boiler so both could run together at certain times. I need to do some research because the finer detail of the hybrid control is crucial to getting the best performance.

Or… we are Cheshire, not a million miles from N. Wales, if you’re still based there. Would be very interested in your consultancy service, if that’s an option….

Hi,

I have to renovate the heating system of my old family house and I am not sure if it is suitable for a heat pump with low temperature radiators. The house is uninsulated but it has 600mm thick stone walls. It has a lot of inertia so, it heats up slowly but it cools down slowly too. I am not sure if I will manage to keep indoor temperatures within a comfortable range without covering all the walls with low temperature radiators. The house is in the north of Spain, so temperatures in winter never go below 0 degrees Celsius. Do you have any advice on that?

Thank you very much.

Lots of truth here. I have an old house -1780- with a later fully insulated extension. The older part has a lining of 90 mm insulation board in the main receptions areas, and is heated by a mix of low temperature abd older radiators. At first the heat was tremendous. So I bought 4 Bluetooth radiator valves and created a 5 zone from one.

Careful programming if these has produced a house that runs at 21 degrees C all day long.

Initial costs were £11 per day at a 13 to 15 degrees outside temperature. Now they run at a cost if £4.60 per day, which is half the cost of my old oil burner. It will improve when my smart meter gets installed and my fuel cost drops by 25%, due to a switch to Octopus Agile tariff.

Id love to hear more about your Agile Octopus experience.

Hi Howard, sounds like you found a good balance for your best requirements. I’d be interested to know more detail about what you have installed. Could you contact me if you have time?

We have recently converted an outbuilding 30 sq.m to a granny flat.

It’s insulated now to meet or exceed current building regulations and the walls are 30cm thick with insulation and timber cladding.

We find a wall mounted heat pump air-conditioning unit, provides instant heat with a max load of only 0.7kwh. The thermostat , timer or smart settings can be controlled by remote, on the machine control panel, WiFi to smartphone or wall mounted controls. Heat pumps don’t need to be harnessed to central heating systems. It’s probably cheaper to put a separate one like ours £599 appliances direct in many rooms in an old property.

Yes, I have know some people having success with this type of system, but others who hate it. I tried one once, but found it draughty and a little noisy. Certainly more suited to an insulated house like yours, where it can be a small unit. Yours has an inverter, so modulates from 800watts down to 450watts, which is great. It will probably struggle in severe weather, but that may not be a problem to everyone.

And a little bit of Fresh filtered Air ideally